This blog focusses on the things that could be useful when considering using, buying or leasing Finite Element Analysis Software. These tips can be used for both future FEA users as well as managers and decision makers who are thinking about starting to use FEA Software, or think about upgrade and expand their existing FEA Software.

For this blog, the following example is used.

Example:

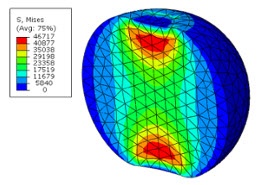

“Company X” produces plastic products for the Life Sciences/Medical Industry in a high volume market. They produce in-house using Injection Moulding, and because of the number of produced products per year, the necessary mould(s) are quite expensive ~ 85k EUR. The products demand a certain technical capability, like: ability to withstand a physical drop test, a certain fatigue life of the product, a certain thermal resistance, a certain interaction with fluids, a predetermined click force, air tight seal under pressure, etc.

So most of these demands and comparison to real-life situation requires a Non-Linear Solver. If you don’t know how to determine whether you should use a Linear or Non-Linear Solver, please refer to one of our older blogs right here: http://info.simuleon.com/blog/why-should-you-consider-performing-non-linear-finite-element-analysis

Besides the non-linear aspect, you might want to consider the availability of an explicit solver, particularly in this example for the drop test. For other situations it can be very convenient to use a different solver when things don’t seem to converge because of fast happening events. Some FEA software do have an explicit solver integrated within the same interface. Others demand the purchase of additional software purely for that purpose.

Till now the example Company X has always created prototypes and physically tested them before investing in expensive production moulds. Obviously the creation of numerous physical prototypes and testing those, doesn’t often come cheap. You also limit yourself to the number of number of possible solutions related to the number of physical prototypes.

1. Determine Your Preliminary Technical Requirements

Congratulations! You have discovered a potential need for FEA Software in your company, or discovered a technical area where more capabilities are needed. Now you are up for the challenge of finding out what you want.

Of course there are many FEA software out there with numerous differences, flavours, costs, user friendliness, CAD-integrated, stand-alone, on premise, cloud based and many other variances.

A good exercise to not be bothered with the numerous functionalities of different FEA software, is to create your own preliminary Technical Requirements list. Try to make a list which covers both short term demands as well as future wishes.

This preliminary technical requirements list might be updated in a later phase because of gained knowledge during the decision making process.

1.1. Short Term Demands (Example)

Industry: Life Sciences

Necessary Capability:

- Pre processing

- Open, read, change and simplify 3D & 2D geometry

- Ability to create 3D & 2D geometry from scratch

- Use material specifications from practical test data

- Clear set-up and interaction

- Solving

- Drop test

- Fatigue

- Thermal

- Fluid Structure Interaction

- Click through / Snap through behaviour

- Plastics & Rubbers

- Seal tightening and closure

- Post processing

- Creation of animations and pictures

- Creation of numerical values, tables and customized graphs

- Usage of quality checks to verify the outcome

1.2. Long Term Demands (Example)

Future wish for:

- Mould Flow Simulation

- Virtual destructive tests (failure)

- Possibility to create simplified GUI

- Coupling with mould flow

- Coupling with CFD software

- Usage of scripts for repetitive tasks

2. Determine Your Necessary Resources

For budget purposes it would be handy to know what the current situation is. For instance the already available in-house hardware and the number of people that will be using the FEA software. These specifications can be mapped to:

- The required hardware specifications

- The required education level for your staff (do they all need to do the same analysis, or will it be divided between generic users and experts?)

- Number of people to be trained (probably not all engineers will be using FEA software, but to make the learning curve more efficient, you might want to consider training at least 2 persons, even when only one will be using it most of the time)

You also might want to consider investigating if your preferred reseller provides FEA consultancy as well. The advantage is that they can help you out when your useful FEA resource won the jackpot or just leave your company, or when you have a too big project to run by yourself. Resellers who also provide FEA consulting tend to have more in depth knowledge and experience than resellers who don’t. We are often being used by our customers to start a project in a technical area where our customers are lacking sufficient current knowledge. And if you are an engineering company, please don’t see us as a threat. We have numerous engineering companies as a customer, and we don’t compete with our own customers.

3. Make a Pre-selection for Possible Fea Software and Evaluate Before You Invest

Based on your technical requirements for both short term and long term, you should be capable of selecting a few options for a possible FEA software. Just be aware that most of the CAD-Integrated FEA software are intended for generalists, whereas most of the standalone FEA software usually have more and better dedicated FEA functionality. Unfortunately some software vendors seem to list functionality while that functionality is really limited or not even used in real life. Of course they like to tick the checkbox, but it is really important to take a deeper technical dive into the actual technical capabilities and not to believe the salesperson on his/her blue eyes.

Most FEA software resellers will be happy and able to assist you with evaluating your technical demands.

When you want to do the evaluation yourself, don’t expect to be an expert in just a few hours of fiddling around with your evaluation license. Best would be to have a training or to join for a free workshop. Just like these for instance: https://www.simuleon.com/events/category/workshops/

During the workshop you will be guided by certified instructors and you will be able to get a good feeling of the technical capabilities of the software and also of the level of the technical consultants:

When you do decide to do the evaluation on your own, try to define your Criteria for Success upfront. It should give a clear idea on what you would like to evaluate, why that is important, and how you will perform that evaluation. Most of the software vendors will help and guide you during this process. This is also a good opportunity to get to know their support methods and quality.

Additionally they most likely can help you with some guided tutorials that you can use to explore some capabilities you haven’t thought of yet. For example: https://www.simuleon.com/abaqus-tutorials/

Depending on your time and how thorough you would like to do you your investigation, you can perform the evaluation / workshops / training for the few FEA software’s you have preselected. Don’t take this decision too light, because it is quite a strategic decision to be made, and switching to a different software later on because your bought the wrong one will cost you a lot of time, money and frustration.

During the deeper technical dive you will get a good feeling of the different capabilities, user friendliness, reseller experience and professionalism, which should be sufficient to define your preferred FEA software, but this is without the costs that are accompanied with your preferred choice.

4. Determine and Compare Direct and Future Costs

Obviously costs of your upcoming FEA software investment are really important. Unfortunately it can be quite a challenge to compare offers against each other. Some vendors offer purchase options, other offer lease or even offer both. If lease is considered, it just comes back as spread costs on your balance, whereas purchase will be written off in a certain amount of years. Some offer you cloud credits, or they have pre-bundled packages with different functionality, others come with a full functionality package and just base their price on the speed/number of CPU’s you would like to run your analysis on.

At the end everything should be included:

- Implementation

- Migration of existing simulation data?

- Training

- Minimum training

- Advanced training

- Necessary Hardware

- Support costs

- Future costs

So now you have added costs to your equation and now what?

Hopefully it helps you to make an overall decision, but don’t forget that in a technical innovative R&D Engineering environment, most important driver for the investment should be the functionality, capabilities, solutions and future possibilities.

5. Your Choice Should Be Future Proof

We don’t have a glass boll to predict the future, but taking the future into account certainly helps to sustain your investment.

A local developed and oriented FEA software solution might do the job when you are not working with other customers outside your country, but when cooperating with international oriented companies it could certainly help choosing one of the bigger FEA software systems who can provide global support in your own native language with training material and documentation in many languages. Scale and the amount of global users usually form solid communities which you can use when you need to outsource some of your FEA work.

FEA software which have robust solvers, but don’t invest that much on development anymore, don’t seem like a sustainable investment. Software companies who don’t invest in continuous development of their existing tools, or refuse to develop new tools could bring you cutting edge solutions today, but will they still be able to in about 5 to 10 years?

Companies like cimdata usually provide reports tailored to the Simulation and Analysis market that can give you an idea how future proof your investment will be and what the amount of market share is for your selected FEA software. Additionally visiting a few applicable FEA software user meetings might tell you how alive that particular group might be in your particular area.

Round-up

Hopefully I have provided you some additional insights which you can use for your search to your best FEA software whatever that might be.

Of course we hope it will be SIMULIA Abaqus :-)

Please be aware we only provide SIMULIA software for Belgium, The Netherlands and Luxembourg. For services and training we can always help you out.

Interested in continuing your journey with us?

(Only applicable for Benelux)

(Only applicable for Benelux)